NEWS & EVENTS

LIFT and Amatrol Announce National Rollout of IGNITE: Mastering Manufacturing Advanced Manufacturing Curriculum for High Schools

Innovative curriculum engages students in new ways of learning and prepares them as multi-skilled technicians for the advanced manufacturing workplace.

In response to the significant need for employees with “upscaled” knowledge and skills in the advanced manufacturing environment, LIFT, the Detroit-based National Manufacturing Innovation Institute, and Amatrol today announced the national roll-out of a new learning system designed to prepare a workforce of highly skilled technicians who understand materials science and have the abilities needed to optimize manufacturing technologies, processes, and systems.

Following successful pilots in three different school districts in Michigan, Ohio and Illinois, IGNITE: Mastering Manufacturing will now be available for implementation by high schools across the nation. IGNITE is an innovative three-year curriculum built around real industry problems and challenges. It uses engaging, technology-infused course materials to inspire student interest and encourage participation in learning. Students completing the curriculum are equipped for success as the next generation of multi-skilled engineering technicians, technologists, or engineers. The program was designed in modules, so it can be rolled out as a one, two, or three-year program.

Three components form the IGNITE curriculum, informing and building off each other to help students develop their skills in a holistic learning environment.

- Materials Science: A series of materials science modules are integrated into the foundational IGNITE manufacturing activities and other courses, such as math and science.

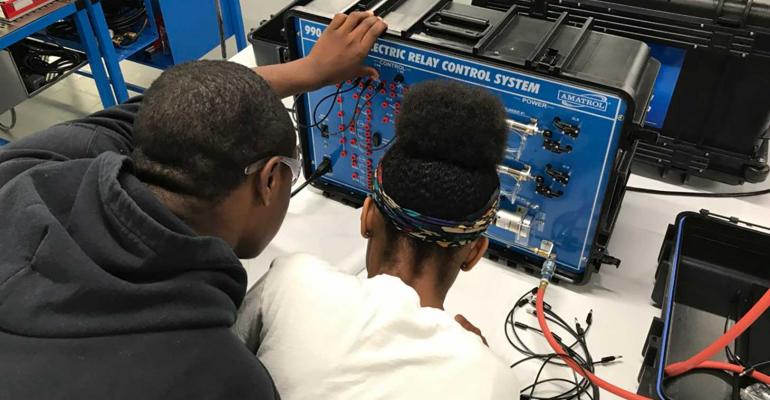

- Advanced Manufacturing Systems and Processes: Representing the most significant portion of the IGNITE curriculum in terms of student time and content, three courses are included: Introduction to Advanced Manufacturing, Advanced Manufacturing Systems 1 and Advanced Manufacturing Systems 2. Each course blends interactive multimedia learning with virtual simulations of manufacturing technologies to help students experience topics in an immersive, project-based environment.

- Capstone Projects: In the final year of the curriculum, students work in teams on a capstone project that uses industry-specific new and emerging technologies to solve real-world problems.

Each lesson in the IGNITE curriculum also provides students the opportunity to learn and practice Common Employability Skills, which are foundational to professional success in any career. They include, for example, communications, teamwork, critical thinking and problem-solving skills.

“The range of employment needs in manufacturing presents broad economic opportunities for prospective workers seeking great jobs and careers,” said Emily DeRocco, senior advisor, Talent Development, LIFT. “The demand for multi-skilled technicians also means significant challenges for manufacturers who need workers with upscaled knowledge and skills. It is imperative, then, that the U.S. teach and train our next-generation manufacturing workforce differently. IGNITE provides the new content and tools to accomplish this.”

IGNITE was developed by a creative team of education and manufacturing experts from three National Manufacturing Innovation Institutes – LIFT which focuses on materials; MxD on digital manufacturing and cybersecurity; and America Makes on additive manufacturing – and Amatrol, a market leader in manufacturing training. They were joined by The Ohio State University and the PAST Foundation.

”Our security as a nation is tied directly to our advanced manufacturing economy, so it is incumbent upon us to fill the ‘missing middle’ and ensure the workforce of the future is growing, prepared and ready to work in this industry where technology is moving extremely rapidly,” said Nigel Francis, chief executive officer and executive director, LIFT. “LIFT, together with Amatrol, is proud to be driving the future of our national manufacturing talent education and development across the nation.”

“IGNITE’s novel approach to education has the potential to attract a whole new generation to the world of advanced manufacturing,” said Paul Perkins, chief executive officer, Amatrol.

IGNITE: Mastering Manufacturing ensures students are prepared for an entirely networked system of manufacturing tools and world-class equipment. In this environment, educated and trained technicians will optimize manufacturing processes and systems. As advanced manufacturing increasingly moves to customization and individualization of products, IGNITE-educated technicians and technologists will be on the forefront of advanced manufacturing in the U.S.

For more information about IGNITE: Mastering Manufacturing, visit www.lift.technology/ignite.

ABOUT LIFT

LIFT, operated by the American Lightweight Materials Manufacturing Innovation Institute, is the Detroit-based, public-private partnership between the Department of Defense, industry and academia, committed to the development and deployment of advanced manufacturing technologies, and implementing talent development initiatives to better prepare the workforce today and in the future. LIFT funded in part by the Department of Defense with management through the Office of Naval Research. Visit www.lift.technology or follow on Linked in at LIFT or on Twitter @NewsFromLIFT to learn more.

ABOUT Amatrol

Amatrol creates innovative, interactive technical learning solutions for industry and education to equip technicians and operators with the skills they need to adapt and thrive in a rapidly-changing workplace. Our passion has led us to the forefront of the Technical Education market in both hands-on, skill-building educational labs and highly-detailed and expansive curriculum. Our technical learning systems are utilized by many types of organizations, including community colleges, industry training centers, high schools, universities, apprenticeship training centers, and vocational training and education centers. Visit amatrol.com to learn more.