Accelerating in American Advanced Manufacturing

Through the development of innovative technologies and talent, LIFT accelerates the adoption of technology and talent between concept and commercialization, building resilience across the American manufacturing ecosystem. There’s a reason we’re the trusted advisor when it comes to guiding U.S. manufacturers toward a more secure and smarter future.

Technology

The LIFT Leading Innovations For Tomorrow technology program designs, builds, tests and verifies new advanced materials, including for hypersonic and other extreme environments, and develops new manufacturing processes and systems.

By connecting the virtual modeling and simulation of materials and processes with the physical world, LIFT accelerates the development time and reduces costs, while driving implementation faster.n.

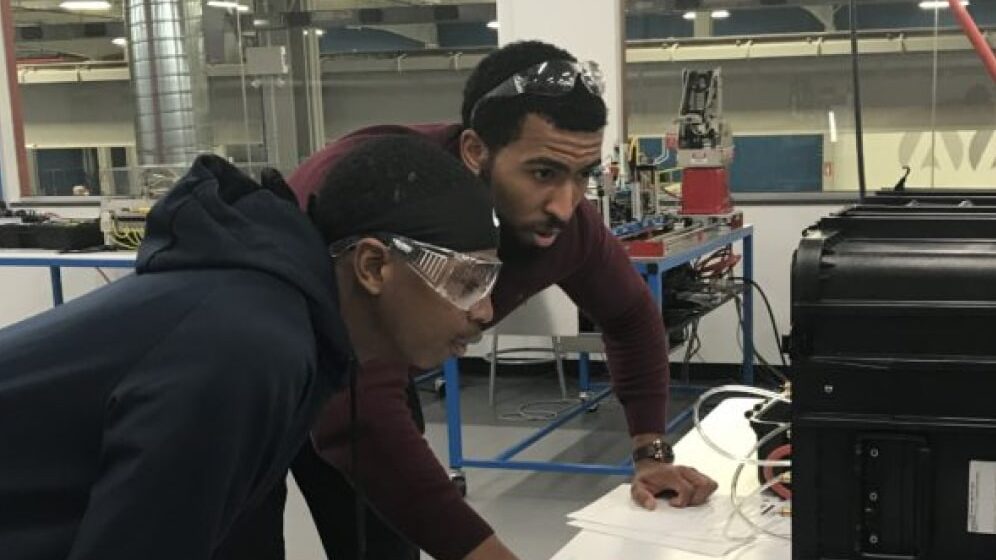

Talent

The LIFT Learning Innovations For Tomorrow Talent Program designs and develops new tools and new venues to support national talent programs.

These programs include new curricula, to ensure the manufacturing workforce of the future, made up of multi-skilled technicians, has the knowledge skills and abilities to successfully work in the advanced manufacturing future.

Government

LIFT recognizes that support of the warfighter is mission critical to the resilience of American manufacturing.