NEWS & EVENTS

Throwing Money at a Talent Problem Won’t Solve It

The increasing pace of change in technology-driven manufacturing calls for more immersive educational models.

For decades, our nation has invested billions of dollars in programs and initiatives to address the disconnection between workforce demand and supply.

However, the advanced manufacturing skills gap still exists. So that leaves the question: If we are investing billions of dollars to correct this problem, where are we falling short?

Unfortunately, investments made are too often responses to perceived reasons for dislocations or unemployment, such as impacts of trade and globalization or economic shifts in various parts of the United States.

For many of us engaged in this field, we know the real cause is more complicated. The nature of work has changed substantially; in every sector, the infusion of technology is redefining jobs and the competencies required for individuals to be successful within their role. And the composition and desires of the workforce have all changed in critical ways.

Four generations of workers now comprise our domestic workforce, for perhaps the first time in history. Each generation has its own strengths and weaknesses, and leadership has fallen behind in understanding and adapting to this complex talent base.

At the same time, our education and workforce development systems have remained remarkably unchanged for decades. The increasing pace of change in technology-driven manufacturing processes and systems calls for accelerated adaptation of education pathways, curricula and pedagogy to produce engineering design experts and a technician workforce with the necessary employability and technical skills to optimize materials, processes and systems.

The United States’ job market has not yet adjusted to these changes. The result has been great inefficiencies in the systems designed to link “the supply” of educated and skilled workers with “the demands” of business and industry.

In truth, the causes of unemployment, under-employment or lack of marketable skills are far less important than understanding these conditions of our workforce and workplaces:

Workers are unsure what knowledge, skills and abilities they need to succeed in today’s manufacturing jobs.

Workers must continually acquire new and often higher-order skills to keep up with the pace of change.

Workers must master an evolving set of competencies.

To help address these issues, it is time to take the classroom out of the school and place students in an immersive learning environment where they not only train, and learn using industry-standard equipment, and address real industry problems and challenges, but also see and experience actual research-development and production work taking place on a 21st-century smart factory floor.

This is the kind of environment LIFT, Lightweight Innovations For Tomorrow, designed and implemented with the LIFT Learning Lab. Located at LIFT’s Manufacturing Innovation Institute in Detroit, it is an immersive learning facility overlooking and, in part, on the shop floor of a Department of Defense-supported innovation institute that is one of 14 regional Manufacturing USA institutes.

The LIFT Learning Lab spans 6,500 square feet and features seven unique labs to prepare the workforce for in-demand manufacturing careers. LIFT provides training leading to industry-recognized credentials and proprietary, company-specific instruction to meet competencies required in today’s manufacturing workplace, and K-12, community and technical college and university programs to educate the next-generation worker.

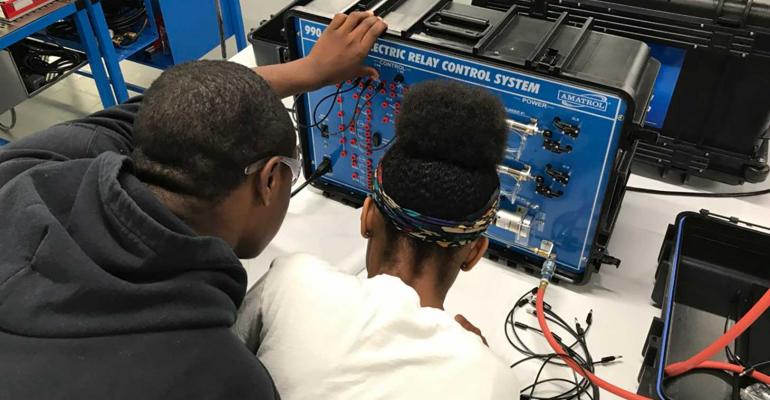

The equipment in the LIFT Learning Lab facility has been curated to showcase robotics and automation principles that underpin “smart factories,” as well as expose students to materials science, metrology and maker spaces for hands-on fabrication.

The LIFT Learning Lab features the latest models of industry-standard equipment—no miniaturized or out-of-date models. Students will learn on the same equipment they will encounter in the workplace, reducing employers’ need to provide additional on-the-job training. Instructors are certified, bring real-world industry experience into their teaching, and are up-to-date on the latest technologies and processes, with many still working in their field, ensuring students’ learning is relevant to today’s manufacturing needs.

The lab also features LIFT’s “IGNITE: Mastering Manufacturing” curriculum, developed in partnership with learning company Amatrol, providing interactive learning solutions to master technical systems and solve problems. It supported by a national partnership led by LIFT with funding from the Department of Defense. IGNITE is a three-year, foundational, competency-based educational program for the “multi-skilled technician” needed in today’s workplace. The IGNITE curriculum couples learning with project-based experiences built around real industry problems and emerging technologies to prepare students for a 21st-century production environment, as well as for additional post-secondary education to become engineering technicians, technologists, or engineers. Among the learning spaces in the lab are the Fundamental Manufacturing Skills Development Lab, CNC Operations and Welding Technicians Training Centers, and the Smart Factory lab.

The national partners supporting IGNITE include: the National Institute for Metalworking Skills, a global leader in providing industry-developed, competency-based skill standards and credentials in precision machining; the PAST Foundation, which helps schools and districts develop transformative learning strategies; ASM Materials Education Foundation, which supports the advancement of scientific and engineering knowledge through education and research; Ohio State University, one of LIFT’s founders, and two other national manufacturing innovation institutes focused on digital and additive manufacturing – MxD and America Makes.

The LIFT Learning Lab is a far cry from a traditional educational facility, with learning occurring in a real, working manufacturing environment and high-tech innovation lab. Students are immersed in new technologies and cutting-edge processes to learn the fundamentals they need to thrive in an advanced manufacturing environment.

To solve the growing skills gap and secure the United States’ manufacturing industrial base, and therefore, our national economy, we must begin to think outside of the classroom. LIFT has taken the first step in doing so with the LIFT Learning Lab and is exploring opportunities to expand the model regionally and nationally.

Emily DeRocco is vice president, education and workforce development for LIFT – Lightweight Innovations for Tomorrow, a Detroit-based public-private partnership.