State of Michigan announces strategy to invest in advanced materials and manufacturing process, joining technologies and advanced manufacturing talent, leading to a $10 million co-investment in LIFT.

February

ALMMII established as a Michigan-based 501c3

June

Detroit selected as new home to LIFT facility

Pictured here: Construction of the Detroit facility in 2014, revitalizing the Corktown area, and providing new job opportunities to Michigan workers

January 2015,

$148 million innovation center opens

Pictured here: A ribbon cutting by the Mayor of Detroit, Members of Congress, Department of Defense officials, ALMMII Board of Directors and other stakeholders.

“What you see here is not just about advancing technology, it’s about advancing people.”

– Detroit Mayor Mike Duggan

Highlights

April

Launch of the first career job training program into Louisville, KY high school. Conexus, Indiana launches work and learn opportunities.

May

Database and computer models developed to predict corrosion in aluminum alloys in airplanes and other transportation

September

Showcased Robotic Blacksmithing at IMTS, kicking off nationwide blacksmithing competition.

October

LIFT launches a 2 year project to develop a more cost-effective means to manufacture lightweight aluminum metal matrix composites (MMCs) for use in large scale automotive and aerospace production. LIFT and Columbus State Community College collaborate for a work study program. 150 students to enroll over 5 year period.

November

NIMS and LIFT partner to form a program for veterans to launch manufacturing careers. Fast Forge program launched.

2016-2017

Additional investments made, $38 million, followed by $50 million funding of advanced manufacturing equipment

In 2016, MakerMinded, a new online STEM learning, competition and program, launches in Tennessee. MakerMinded platform connects students to over 150 “leading edge STEM experiences”.

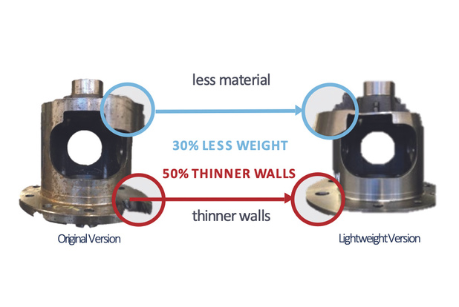

Thin-Wall Casting Project Success:

The project developed a new ductile alloy and showed a 30% weight reduction in the cast prototype parts, including a 50% reduction of walls thickness of parts.

December 2016, LIFT agrees to bring in the largest linear friction welder to the Detroit facility, increasing lightweight research and development. The friction welder significantly eliminates wasted materials and post machining.

NIMS, LIFT, ivy Tech release new skills credentials and training for manufacturing jobs in midwest auto corridor, to fix the gap. 9 career paths are created.

Expert Educator Team created to identify how universities can modify curriculum and certifications to meet new job demands in lightweight technologies, materials and processes being developed by LIFT.

LIFT and IACMI launch national online manufacturing Learning Hub, for educators and students, in the first open source repository to provide tools and materials information to teach tomorrows workforce.

LIFT Off webinars series launched to give small businesses a platform to talk about their emerging technologies.

Highlights

March-December

LIFT reports on critical imperatives universities must take to improve engineering work & learn models. Expert Educator Team

releases new set of recommendations aligning technology and

talent development.

May

LIFT and The Center unveil an aftermarket lightweight car frame

that can morph into any wheelbase, vehicle length and width

without additional tooling. Applications include both military and

the aftermarket vehicles.

June

LIFT introduces certification courses in Ohio, Case Western.

July

MakerMinded program and competition expands into Indiana, Idaho, West Virginia.

LIFT creates a new process for shipbuilders to reduce production costs by 13%, improve build time, while reducing distortion of lightweight materials by 30%. The innovative computer modeling predicts where distortion or warping will occur when steel plates are welded together.

December 2018, Lifeline Fire hose fitting developed, allowing delivery of oxygen to firefighters through the same hose that delivers water to fire.

IGNITE advanced

manufacturing curriculum launches in 2019.

The program’s success

leads to expansion

across the U.S.

April

LIFT and Center for Automotive Research (CAR) test and evaluate mixed material joining technologies, to develop an open-source catalog.

September

LIFT and Michigan startup Loukus Technologies explore magnesium alloy extrusions to reduce weight of auto and defense applications. Eck Industries joins in October.

- LIFT works with institutes, Ford & GM to rapidly produce ventilators due to Covid crisis in hospitals.

- LIFT collaborates with University of Michigan to develop an innovative ventilator valve enabling a single ventilation device to support two individuals.

- Advancement of additive manufacturing, including wire arc additive manufacturing (WAAM) and cold spray technologies

- Development of agile and smarter manufacturing processes such as incremental sheet forming, a more flexible and affordable method of manufacturing components.

industrial equipment and expertise. For others, it’s the opportunity to de-risk early-stage technology through collaborative R&D.”

Highlights

March

Ricardo Defense awarded $89 million contract for HMMWV improvements that reduced fatal rollovers by 74%.

LIFT opens second facility to house DOD program management in Michigan.

July

Smarter Manufacturing Podcast launched.

September

Arris, Army, LIFT to lightweight combat vehicles through unique additive manufacturing process.

November

LIFT launches robotic training program

LIFT launches the Girl Scouts’ Think Like an Engineer Journey to encourage career exploration in advanced manufacturing and engineering, to help impact the gender gap in science and engineering fields.

Siemens and Kearney make a significant investment in LIFT facility. Digital Twin Smart Factory created, the manufacturing Smarter Digital Future Showcase.

April

Michigan Tech University and LIFT partner to design future additive manufacturing materials and processes.

June

LIFT kicks off next round of hypersonics material development programs

August

“Energy conservation process” pilot program launched to produce electrochemical separators for DoD energy systems at the institute.

October, LIFT hosts A2M2X (Accelerating Advanced Materials and Manufacturing Exchange) conference to drive collaboration and advancement in materials science, manufacturing processes, systems engineering and talent development.

December 2022, LIFT announces plan to expand

Institute Operations into Puerto Rico

advanced manufacturing technology and talent development.

LIFT’s Operation Next Program Receives $2 Million in Funding from State of Florida to Expand Training for Transitioning Soldiers, Military Spouses and Veterans for Careers in Advanced Manufacturing

2024

Marking a Decade of Achievement, Leading Future Advancements

As we look forward, we are committed to our mission as a national manufacturing institute, actively broadening

our operations into new territories such as Florida, Puerto Rico, and other regions. We continue to build on our

existing foundation in technology and development, by connecting advanced materials, manufacturing processes, systems engineering and talent, in support of our national defense and economic security.