LIFT: Leading Innovations For Tomorrow

We accelerate the design, build, and testing of new materials and processes by connecting advanced materials, manufacturing processes and systems engineering to drive transformational change across manufacturing.

Technology By the Numbers

Here are just a few of the vital statistics showing LIFT’s impact in R&D, material and process advancement in the manufacturing sector.

Technology projects since 2014 involving large OEMs & small manufacturers, employing thousands nationwide

Active Partnerships

Includes large OEMs, the top national academic and research institutions, small and medium-sized manufacturers, along with start-up organizations, each working in concert to position the United States as the global leader in advanced manufacturing

In state-of-the-art advanced manufacturing equipment

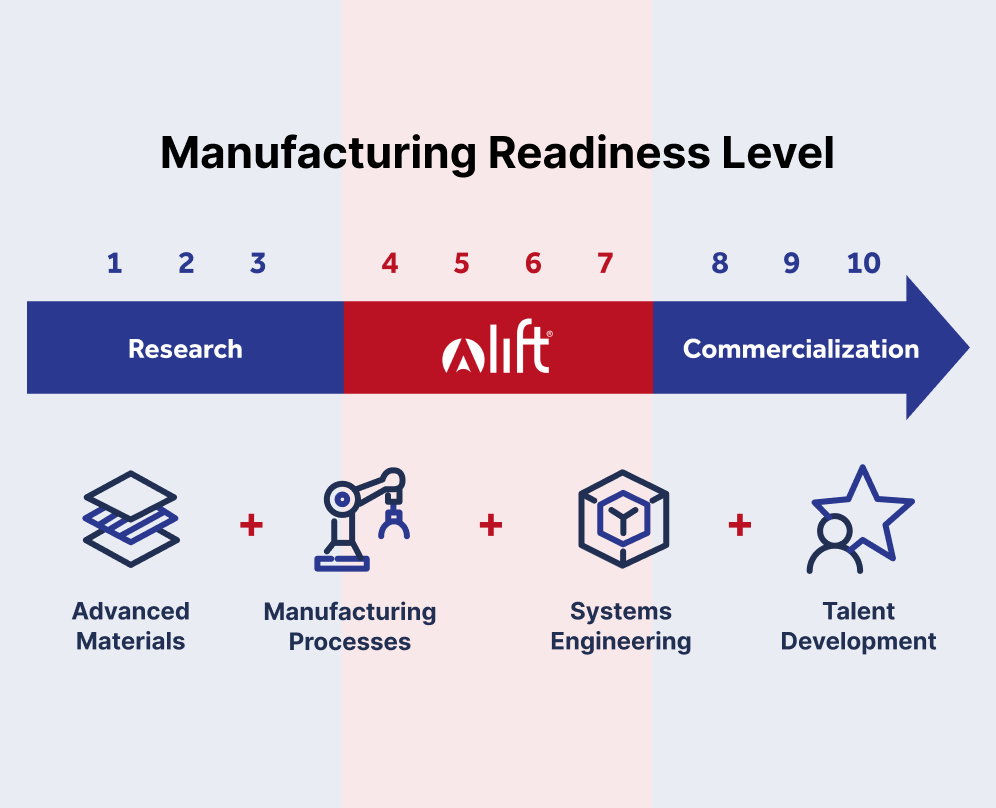

Bridging the Gap in Manufacturing Innovation

Accelerating advanced technologies into manufacturing, scale up, and commercialization.

Connecting digital engineering with physical manufacturing, LIFT accelerates technologies across the “valley of death” to advance concepts from research to commercialization, and accelerate adoption by both industry and the warfighter.

LIFT’s Technology Pillars

Digital Engineering

Developing and utilizing virtual models, in advance of physically building materials or manufacturing components, to predict outcomes and improve efficiency.

At LIFT, we are using digital engineering to develop a suite of digital tools, including modeling & simulation, Integrated Computational Materials Engineering (ICME) middleware, and data analytics throughout the digital thread to accelerate material development.

Advanced Materials

Accelerating the adoption of advanced materials by understanding the characteristics of current materials, or developing new materials – including metallics, ceramics, composites and others.

At LIFT, we focus on advanced materials and their characteristics to ensure the material is the right one for the intended purpose.

Manufacturing Processes

Leveraging current processes, or developing new, connected processes, based on materials and/or purpose, to manufacture components more efficiently and effectively.

At LIFT, we study the manufacturing process holistically, whether it be conventional, augmented, automated, or large scale. We also view the process based on the materials being used and the joining or coating needed post-process.

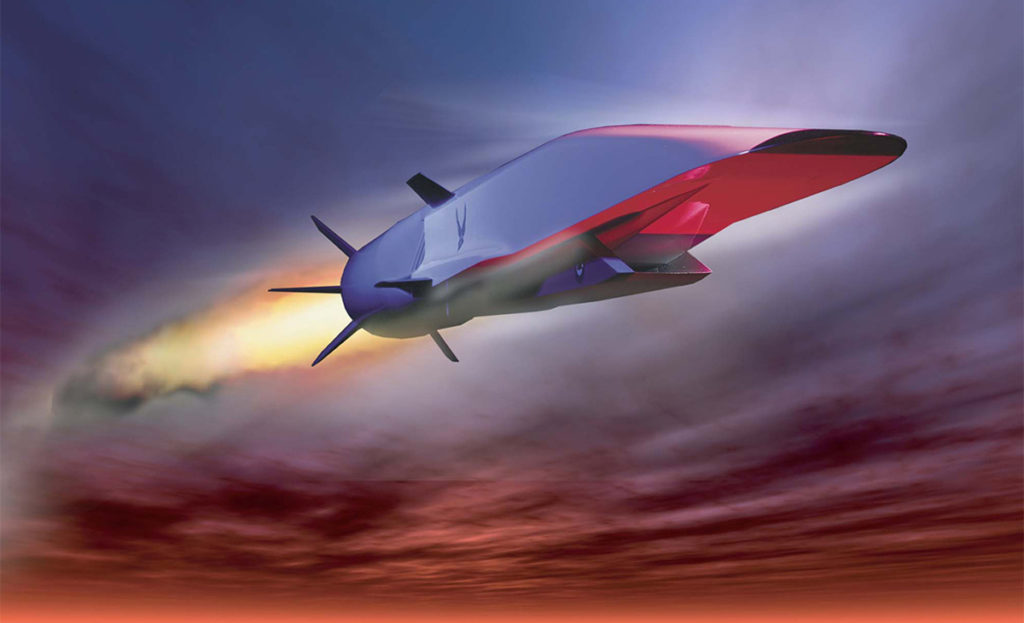

Verification & Validation

Ensuring the manufacturing process produces either a material or component that is fit for purpose.

At LIFT, we verify, utilizing data analytics and unique measurement tools, the end result of the material selection and manufacturing process are suited for extreme environments, including hypersonics, ballistics, blast, and more.

Scale Up & Commercialization

As projects are launched, LIFT works to understand where the advanced material or manufacturing process fits in the existing supply chain for commercialization or if there is additional work to be done to qualify or certify them for scale up and future adoption.

LIFT Technology Impact Stories

LIFT and its partners accelerate technology forward into the hands of industry and the warfighter.

From saving service members’ lives to saving the industry and the Department of War time and money, we continue to Drive American Advanced Manufacturing into the Future.

INTRODUCING LIFT’S NEW STATE-OF-THE-ART

Advanced Metallic Production and Processing Center

LIFT, the National Advanced Materials Manufacturing Innovation Institute, is now producing custom alloys to accelerate material innovation and support the needs of the American Defense Industrial Base. We specialize in small-batch production, catering to every stage of the development cycle—from material development and production to part manufacturing and inspection.

Project Calls are opportunities to solve challenges

LIFT’s Project Calls offer our members the opportunity to submit proposals on solutions designed to solve challenges and Drive American Advanced Manufacturing Into the future. Project Calls can either be directed projects on specific topic areas, from our federal partners or new ideas you and your organization might have. Whichever form they take, each Project Call will have its own unique membership and submission requirements and funding opportunities to Drive American Advanced Manufacturing Into the Future.

LIFT Technology Resources

LIFT’s facility is a 100,000 square foot technology accelerator and pilot facility which serves as a showcase, highlighting “the art of the possible” for the future of manufacturing. It’s a sandbox where we design, build, and test new materials, processes, and systems for the future of American manufacturing.

LIFT Manufacturing Equipment

- Digital Twin Smart Factory Showcase

- Linear Friction Welder

- Extrusion Press

- Plasmatreat Cell

- Wire Arc Additive Manufacturing Cell

- Incremental Sheet Forming Cell

- EOS M 290 Industrial Metal 3D Printer

- Hot Isostatic Press

- Siemens Controls

- CNC Mill

- CNC Lathe

- CT Scanner

- Connected Digital Thread

- Flexible Robotic Joining System

- Fully Equipped Machine Shop

- Fully Equipped Metrology Lab

LIFT Member Services

- Technology Transfer

- Technology Roadmapping

- Portfolio Management

- Program Management

- Knowledge Library

- Start-up Support

- Spin-off Support

- Rapid Prototyping

- Contract Research and Development

- Reverse Engineering

- Physical and Virtual Try-out

- Metrology Services

LIFT Technology Partners

LIFT’s technology partners include large, global corporations and small, startup companies and everything in between. From original equipment manufacturers (OEMs) to materials suppliers and software providers, each of them is committed to Driving American Advanced Manufacturing Into the Future.

Connect With Our Technology Team

Contact the LIFT technology team to learn more about how we can support your smarter manufacturing goals and help you connect materials, processes, and systems. We look forward to helping you achieve your technology goals.

"*" indicates required fields