NEWS & EVENTS

Raytheon Technologies Awarded Hypersonics Challenge Project by LIFT, Department of Defense

Project aims to speed the development of advanced materials for hypersonic systems using modeling & simulation

DETROIT – LIFT, the Detroit-based Department of Defense manufacturing innovation institute, along with the Department of Defense (DoD), today announced the launch of one of the institute’s Hypersonics Challenge projects with Raytheon Technologies.

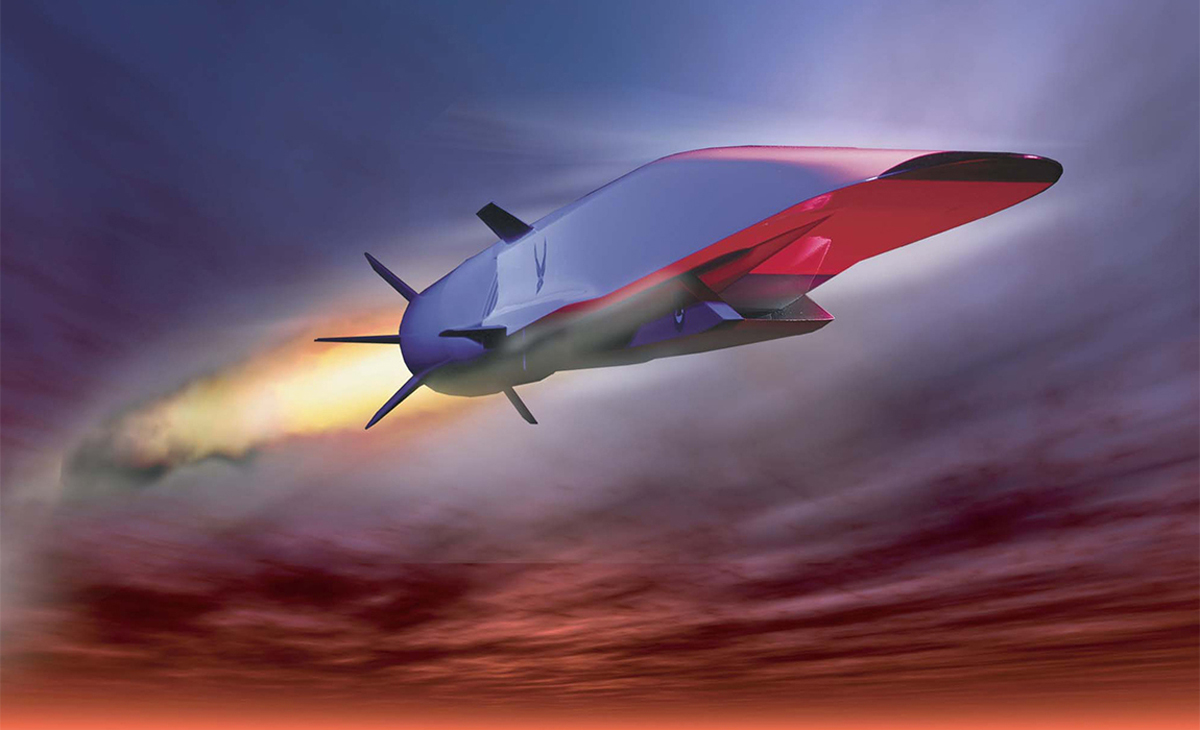

The project is investigating the use of modeling and simulation to speed the development and adoption of new, advanced high-temperature materials required for hypersonic applications. It will be led by the Raytheon Technologies Research Center (RTRC) with support from the company’s Raytheon Missiles & Defense (RMD) business. Operating at speeds of Mach 5 or higher, hypersonic and counter-hypersonic vehicles are among the Department of Defense’s top priorities, as well as the development of a safe and secure domestic supply base.

“Raytheon Technologies has been helping the customer advance hypersonic capabilities for the last decade,” said RTRC Director and Raytheon Technologies Vice President of Research Andreas Roelofs. “At the same time, we’ve been growing our world-class expertise in high temperature materials, structural mechanics and advanced manufacturing. Now we’re combining all these areas with machine learning to create fast and efficient ways of developing materials to build the next generation of hypersonic vehicles.”

This project has been launched as part of the Hypersonics Challenge, which was held in 2021 by LIFT and the DoD Manufacturing Technology Program, overseen by the Office of the Under Secretary of Defense for Research and Engineering. The challenge sought proposals on three specific topics critical to the materials science and manufacture process of hypersonic vehicles.

In its project, RTRC will be developing models to predict the thermomechanical properties of high-temperature Carbon/Carbon (C/C) composite materials for hypersonic applications. The models will connect the properties with the underlying architecture and defect structures, so that both the material and structural design can be optimized in a concurrent manner. Such a model-based digital framework can shorten the material development time by minimizing the current trial-and-error approach toward finding the best microstructure/properties as well as associated conditions such as manufacturability.

“The trial-and-error approach to material development is time-consuming and expensive,” said Rajesh Kumar, project lead for RTRC. “This is especially significant for high-temperature composites as their process turnaround times are on the order of months, so a model-based approach is necessary for attaining the targeted properties and to produce components with the optimal fiber architecture and microstructure.”

“New materials, and the ability to predict their characteristics, are at the heart of our work in hypersonics,” said Nigel Francis, Chief Executive Officer and Executive Director, LIFT. “Ensuring not only the performance of a new material, but its manufacturability, are key to moving the needle, not only in hypersonics, but for manufacturers across industry.”

The Raytheon Technologies project is one of several projects awarded through the challenge. Project awards were determined by a team consisting of LIFT and the Department of Defense. Decision criteria includes technological merit; technology readiness level (TRL) and manufacturing readiness level (MRL); funding requirements; cost-share commitment; ITAR compliance: and LIFT member engagement.

So far, LIFT and the DoD announced the first Hypersonics Challenge have awarded and kicked off Hypersonic Challenge projects with ATC Materials, Inc. and Lockheed Martin.