NEWS & EVENTS

Michigan Technological University and LIFT Partner to Design Future Additive Manufacturing Materials and Manufacturing Processes

Projects include designing a powder metal atomization chamber, enabling the creation of new alloys for additive manufacturing, and developing roadmaps for alloys to use in hypersonics

DETROIT – LIFT, the Detroit-based Department of Defense manufacturing innovation institute has partnered with Michigan Technological University to develop custom powdered metal alloys and road mapping the use of current alloys for hypersonics applications.

The first project, which took place in 2022, was funded through LIFT’s U-LIFT program. Four undergraduate teams made up of four students each designed a powder metal atomization chamber, melting, atomization, and collection systems. “The results of their work will enable the creation of new alloy metal powders for additive manufacturing research, design, and prototyping,” said Paul Sanders, Patrick Horvath Endowed Professor of Materials Science and Engineering. Sanders served as faculty advisor for all four teams.

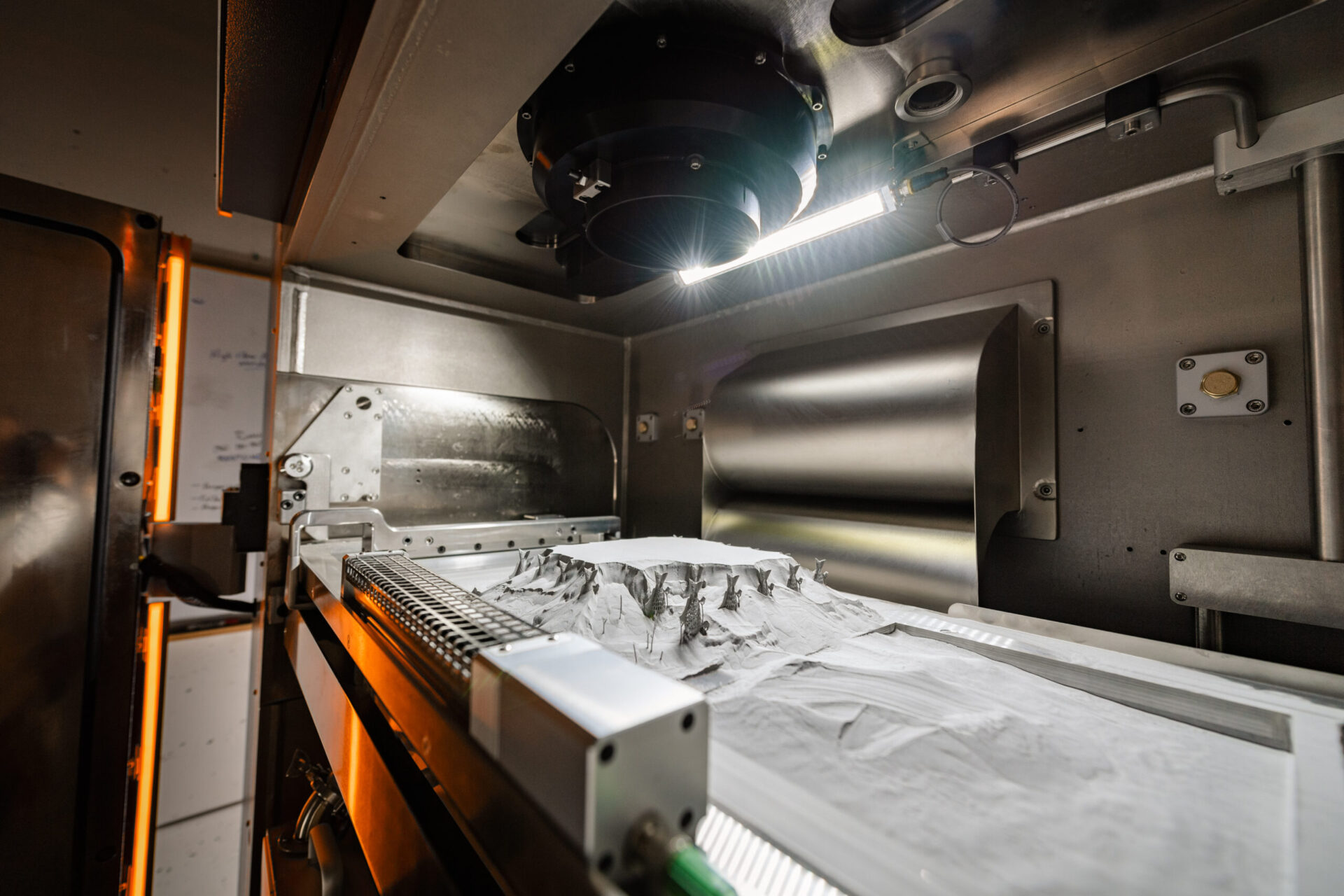

The students’ design, a modular 10-foot-tall chamber, pours molten metal into a funnel and then atomizes it into the chamber though a high-pressure, gas nozzle, thereby creating the powdered metal which is collected at the bottom.

While atomization is a standard technique for producing powders for metallic additive processes, there is limited production capability for custom alloys. This new chamber, as designed, has the ability to atomize about 88 lbs. (40 kg) of metal, including ferrous metals, nickel-based alloys, and aluminum-based alloys.

“This atomization capability is needed because current powders for metal additive development projects are expensive and have long lead-times,” said Sanders. “This chamber, if built and deployed, will provide for improved powder additive alloy design faster and at less cost across industry.”

“Currently, the available quantities for custom powder alloys are either too small for us to do much with, or too large,” said Noel Mack, Chief Technology Officer, LIFT. “The possibility of creating create customer powders in specific amounts could speed up our innovation processes of future applications, such as materials for hypersonics, and therefore speed up the adoption by industry.”

Michigan Tech is also working with LIFT on its ongoing Hypersonics Thermal Management and Material Acceleration programs, both funded through the Department of Defense, to develop roadmaps for alloy and process development for commercial off-the-shelf materials intended to be additively manufactured for use in a hypersonic environment.

ABOUT LIFT

LIFT, operated by the American Lightweight Materials Manufacturing Innovation Institute, is the Detroit-based, public-private partnership between the Department of Defense, industry and academia, committed to the development and deployment of advanced manufacturing technologies, and implementing talent development initiatives to better prepare the workforce today and in the future. LIFT funded in part by the Department of Defense with management through the Office of Naval Research. Visit www.lift.technology or follow on LinkedIn at LIFT or on Twitter @NewsFromLIFT to learn more.

ABOUT MICHIGAN TECHNOLOGICAL UNIVERSITY

Michigan Technological University is a flagship technological public research university founded in 1885 in Houghton, Michigan. The University offers more than 120 undergraduate and graduate degree programs in science and technology, engineering, computing, forestry, business and economics, health professions, humanities, mathematics, social sciences, and the arts. The rural campus is situated just miles from Lake Superior in Michigan’s Upper Peninsula and is home to more than 7,000 students.