NEWS & EVENTS

LIFT Kicks Off Next Phases of Hypersonic Materials Development Work

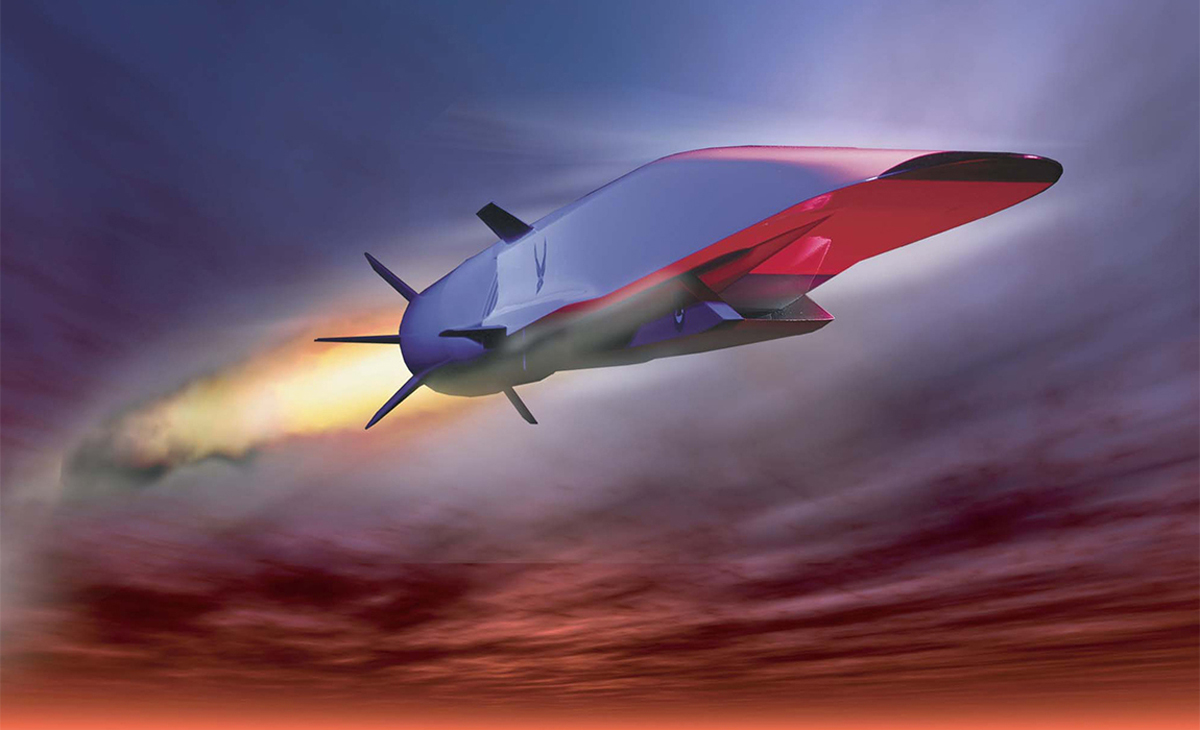

Projects to continue critical work on behalf of the Department of Defense in materials acceleration and thermal management for hypersonic vehicles.

DETROIT – LIFT, the Detroit-based Department of Defense national manufacturing innovation institute today announced it, along with its ecosystem partners, has kicked off the next phase of its Hypersonics Thermal Management and Hypersonics Material Acceleration programs.

The new program phases follow on LIFT’s original work on those two topics, both of which were launched in 2021 and are expected to wrap up this year. Operating at speeds of Mach 5 or higher, hypersonics and counter-hypersonic vehicles are among the Department of Defense’s top priorities, and understanding the materials required to survive these speeds is critical to further developing those vehicles.

“Understanding materials characteristics is at the core of everything as we look to manufacture the components of the future, particularly those which need to travel in excess of 4,000 miles per hour,” said Nigel Francis, CEO & Executive Director, LIFT. “We are proud to be leading the effort in developing the materials and processes which will lead to transformational change in U.S. manufacturing, enabling us to leap ahead of our global competitors.”

The first phase of LIFT’s material acceleration program focused on advancing metallic and ceramic materials and manufacturing processes involved in developing components for high-temperature and hypersonic applications. That work, with partners including Friedman Research Corporation (FRC), Michigan Technological University (MTU), University of Central Florida (UCF), University of Arizona (UofA), Alfred University, the University at Buffalo, Spectrum Engineering, and Hexagon, included development of integrated computational materials engineering (ICME) material digital twins, material property assessment, alloy development for hypersonic applications, and dissimilar material joining.

For the second phase of material acceleration work, LIFT will continue partnering with FRC and UCF while adding partnerships with Exothermics and Materials Research & Design (MR&D) to extend the advancement of ceramic matrix composites (CMCs) produced via reactive melt infiltration, as well as metallics produced via large deformation processing, for use in hypersonic applications.

The first phase of LIFT’s thermal management program advanced metallic materials and manufacturing processes used in high-temperature thermal applications including those produced by powder-based additive manufacturing techniques. ICME material digital twins were produced and validated against metal alloys to drive alloy development for the hypersonic environment. LIFT partners in phase one included FRC, UCF, UofA, and MTU.

In the second phase of the thermal management program, LIFT will work with FRC and UCF to advance the prediction of hypersonic material performance to hypersonic-relevant materials which benefit from functionally graded optimization and are manufactured by Direct Current Sintering (DCS).

LIFT’s work in hypersonics inaugurated earlier in 2021 with the $3 Million “Hypersonics Challenge” for the U.S. manufacturing industrial sector. The challenge invited industry to provide solutions in materials and manufacturing of hypersonic vehicle systems. Those answering the challenge call:

- ATC Materials, Inc.: Demonstrating the repeatable and reliable production of RIPS molded radio frequency (RF) material.

- Boeing: Focusing on powder metallurgy refractory metal matrix composites and in-situ monitoring development.

- Lockheed Martin: Improving cost competitiveness and quality of high-temperature capable hypersonics components.

- Raytheon Technologies: Developing models to predict the thermomechanical properties of high-temperature Carbon/Carbon (C/C) composite materials.