NEWS & EVENTS

LIFT, Heller Machine Tools to Install New 5-Axis Machining Center in Detroit Lightweighting Facility

Contact:

Joe Steele

LIFT

313-309-9132

jsteele@lift.technology

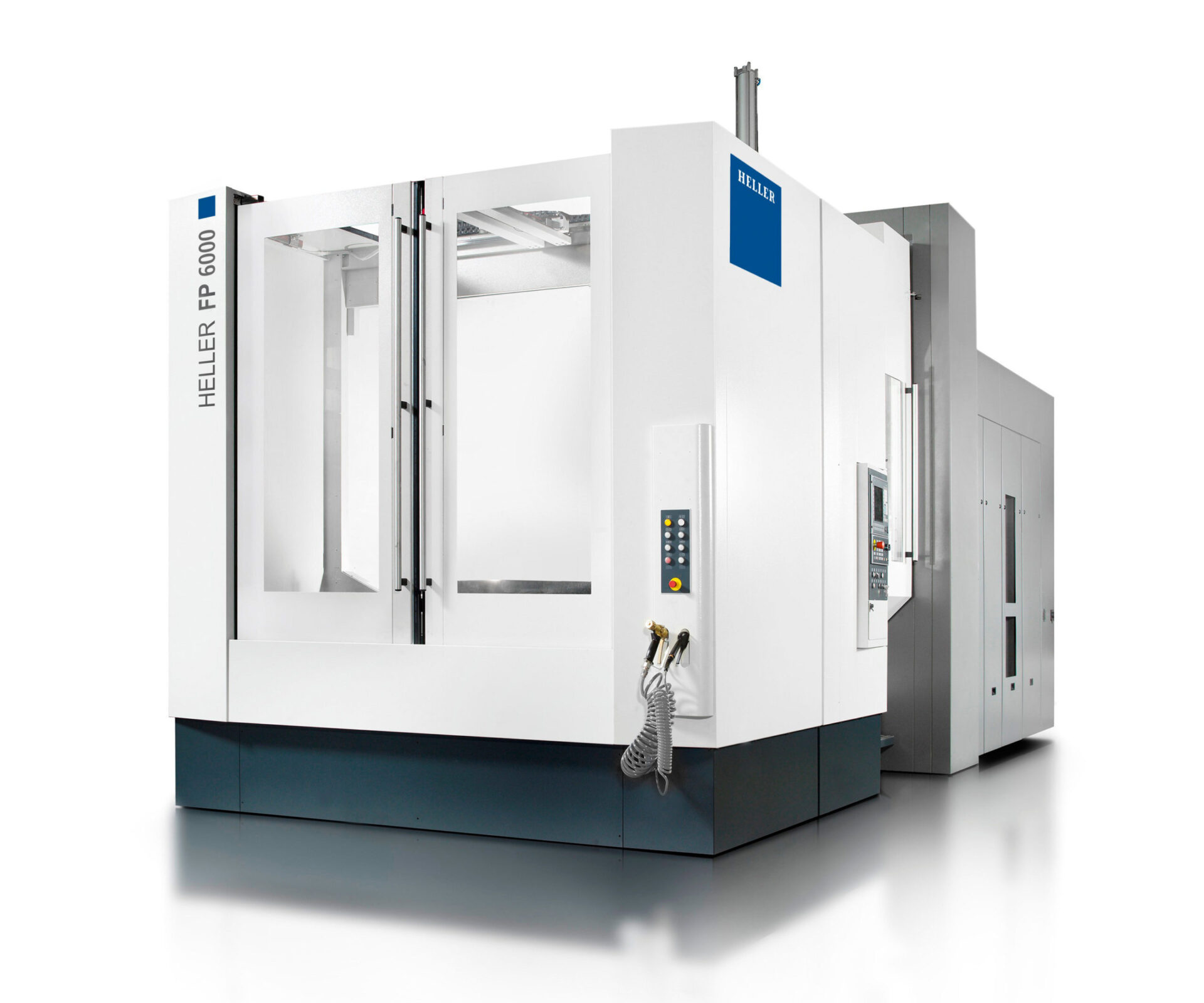

DETROIT – LIFT – Lightweight Innovations For Tomorrow, a Manufacturing USA institute, and Troy-based Heller Machine Tools today announced an investment in a $1,500,000-advanced 5-axis FP 6000 machining center at LIFT’s lightweight innovation acceleration center in Detroit. The new high-tech equipment will be used to develop new machining strategies for lightweight materials across industries.

“Our work is all about lightweight innovation and that means smart minds and leading edge equipment to bring transformative ideas to light,” said Chris Conrardy, interim executive director, LIFT. “Our premiere applied R&D center for metalworking benefits greatly through our important collaborations with organizations like Heller Machine Tools. With them, the possibilities are endless.”

The HELLER FP 6000 is capable of machining five sides of a workpiece, providing the highest available cutting capacity along with a quality machined part surface finish. Leveraging the 5-axis motion of the tool for rapid positioning and the machining spindle, which can reach 8,000 rpm, the FP 6000 leads to reduced machining cycles on complex parts. Additionally, its versatility makes it suitable for many types of applications in Oil & Gas, Aerospace, Agriculture, Construction, Defense, Automotive and all other Metal Cutting Applications.

“Our partnership with LIFT provides us with the abiility to not only showcase and demonstrate our technology, but also help other LIFT members achieve their lightweighting goals,” said Steve Pegram, vice president of Heller Machine Tools.

“We are looking forward to what’s next – now and in the future.”

Equipped with a swivel-head unit and a pallet changer handling a 630×630 mm table, the FP 6000 has a pallet change time of 13 seconds, tool change time of 5.9 seconds chip-to-chip, and acceleration of 4 m/s²–all of which helps minimize non-machining time. The machine can accommodate workpieces weighing up to 1,400 kg (3,086 lbs.) within a work area of 1000 mm in X and Y axes, 1,300 mm in Z.

The FP 6000 machining center is expected to be installed at LIFT by fall 2018.

ABOUT LIFT

LIFT, operated by the American Lightweight Materials Manufacturing Innovation Institute (ALMMII), is a Detroit-based, public-private partnership committed to the development and deployment of advanced lightweight metal manufacturing technologies, and implementing education and training initiatives to better prepare the workforce today and in the future. LIFT is one of the founding institutes of Manufacturing USA, and is funded in part by the Department of Defense with management through the Office of Naval Research. Visit www.lift.technology or follow on Twitter @NewsFromLIFT to learn more.