NEWS & EVENTS

Detroit high schoolers train for next-generation manufacturing careers in new LIFT Learning Lab

It’s one thing to tell high schoolers about the challenging, rewarding career opportunities available in today’s high-tech manufacturing industry.

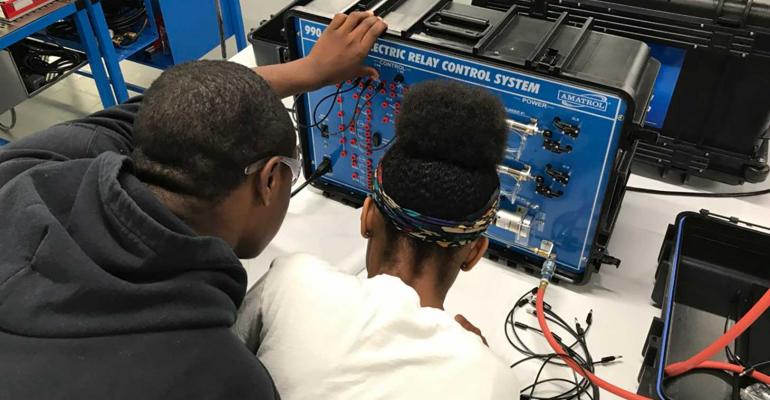

But each school day about 100 local high schoolers get to see that firsthand as they operate real-world manufacturing equipment in the LIFT Learning Lab.

LIFT is a Detroit-based national institute focused on advanced materials research and development for the manufacturing industry. The public-private partnership is committed to preparing the workforce through upskilling and reskilling along with ensuring a pipeline of talent to drive the industry forward.

In August LIFT opened a 6,500-square-foot learning lab that’s catered toward training K-12 and college students as well as manufacturing workers looking to learn new skills. It’s located inside LIFT’s Manufacturing Innovation Institute, a 100,000 square-foot research and development center in Corktown.

About 100 students from Detroit’s University Prep Science and Math High School are participating in a three-year mechanical engineering program at LIFT in lieu of a classroom-based physics credit. The program offers these students exposure to the world of engineering and manufacturing beyond what they could learn inside a classroom, said Kevin Kerrigan, LIFT’s vice president of business development.

“On a daily basis, the kids coming through the program get to see what’s happening in the real world and get to see that it’s not just about what they’ve read about or what their parents have talked about,” Kerrigan said. “The manufacturing industry in the US is moving at a tremendous rate and is probably one of the most sophisticated industries in the U.S. today.”

LIFT offers its IGNITE: Mastering Manufacturing Curriculum to students and current workers looking to learn welding and CNC operations. The facility also includes labs that feature robotics, computer/virtual reality and materials science and project fabrication.

The program continues to expand as its leaders look at other types of curriculums and programs catered to different regions, companies or industry areas such as autonomous vehicles and next-generation mobility. While automotive manufacturing may be shifting from internal combustion engines toward more electrical systems, the fundamental skills needed for these jobs don’t change, Kerrigan said.

In 2020 the organization plans to grow the number of students utilizing the lab as well as look for other areas of Michigan and the United States to open another lab, Kerrigan said. They’re also working on bringing equipment and software to the lab that will allow students to get a better understanding of how a smart factory operates.

As manufacturing continues to develop and rely on more advanced robotics and artificial intelligence, technology will be the area that differentiates the U.S. in manufacturing going forward, Kerrigan said. It’s an opportunity to lead the world in next-generation manufacturing, he said.