NEWS & EVENTS

LIFT Launches CNC and Welding Certification Courses

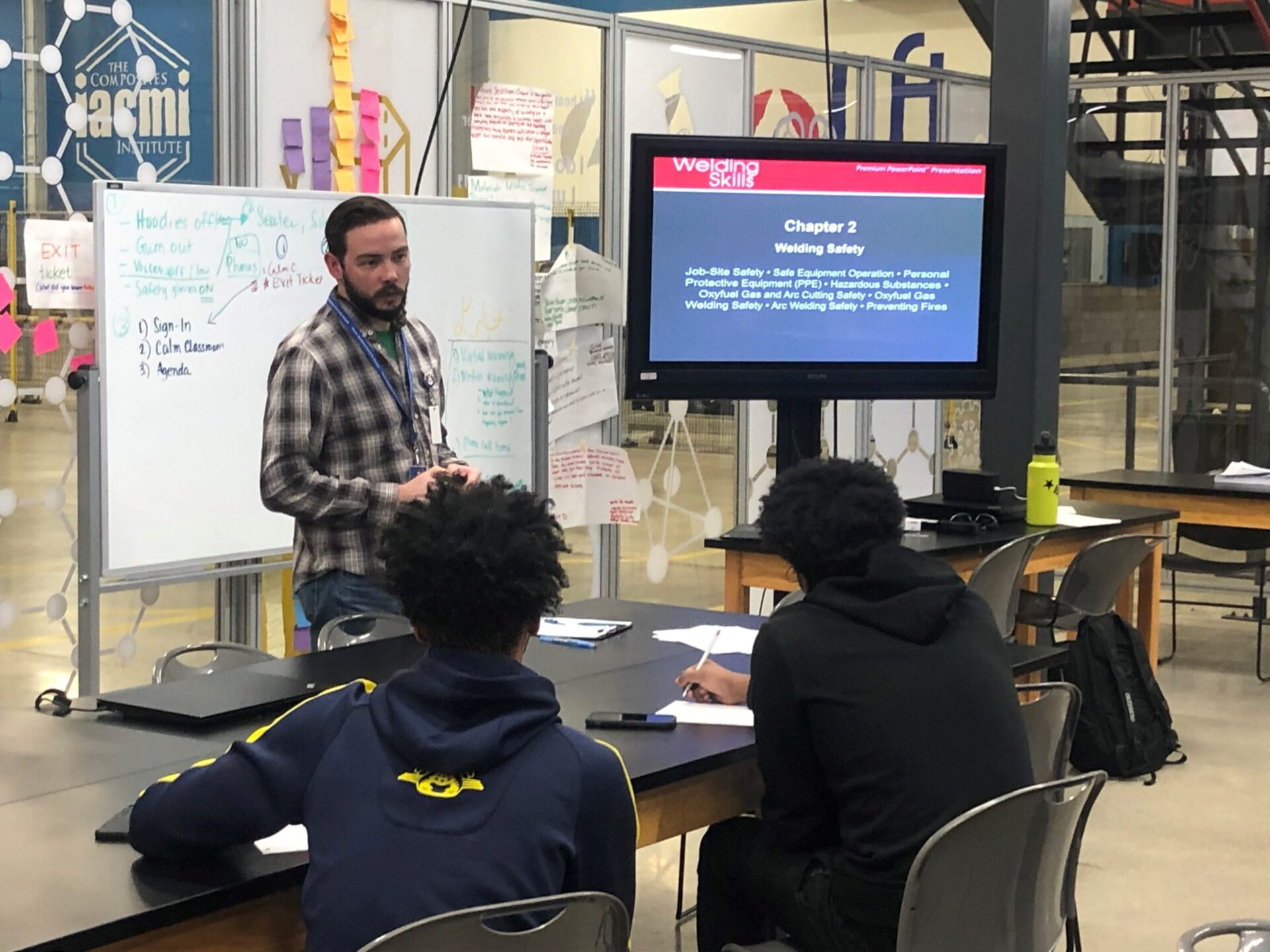

LIFT recently launched its first on-site CNC and Welding Certification courses, providing the opportunity for students to learn new skills for some of the most in-demand manufacturing jobs.

The classes, held at LIFT’s Detroit headquarters utilize the LIFT Learning Lab which opened last fall and is designed with eight unique labs – including welding and CNC – to prepare students for the most in-demand manufacturing careers.

LIFT’s CNC Operations program prepares students to operate CNC mills and lathes. Utilizing curriculum aligned to NIMS Machining standards, this course covers: Machine maintenance, safety, print reading, measurements, inspection, cutting tool assembly, geometrical dimensioning and tolerancing (GD&T), and hands-on project-based learning done in the Learning Lab.

LIFT’s Welding Technician program prepares students to become entry-level welders in either Gas Metal Arc Welding (MIG) or Gas Tungsten Arc Welding (TIG). Utilizing curriculum aligned to the American Welding Society SENSE Level I standards, this course covers the required knowledge, attitude, skills, and habits required to perform routine, predictable, repetitive, and procedural welding tasks. Topics include: Safety, Occupational Orientation, Gas Metal Arc Welding (GMAW) or Gas Tungsten Arc Welding (GTAW), four Thermal Cutting Processes, and Welding Inspection and Testing.

According to a recent study by Deloitte, the advanced manufacturing skills gap may leave an estimated 2.4 million positions unfilled by 2028, with a potential economic impact on the U.S. of $2.5 trillion.

LIFT is addressing the skills gap by providing educational opportunities not only for workers looking to gain new skills, but by providing exposure advanced manufacturing to middle and high school students through the institutes IGNITE: Mastering Manufacturing curriculum.

For more information on the LIFT Learning Lab, visit www.lift.technology/learninglab.